With a large amount of work with electric wires (replacing highways, repairs, etc.), you can not do without a special device for exposing the ends of the wiring. There are special mechanisms to facilitate this time-consuming process, but few people know that in five minutes, from a practically available means, you can make a simple and effective device for cleaning cables of different diameters (from 10 mm or less).

What you need to have on hand

- A piece of plastic pipe for wiring (outer diameter 20 mm);

- Large blade from a clerical knife (width 16 mm);

- Plugs from the mounting box (2 pcs.);

- Of the tools we need a drill with a set of drills for metal (wood), a saw, a sharp knife, sandpaper, tape measure, marker and vise.

Knife holder preparation

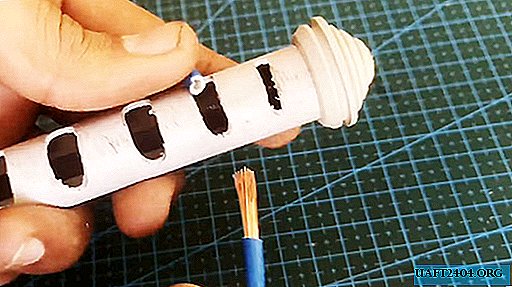

To begin, cut a piece of pipe with a length of 14 cm. Using emery paper and a sharp knife, we remove the burrs from the cut. We mark the pipe with an interval of 2 cm so that we have 6 marks.

We will need drills with a diameter of 10, 8, 6, 5, 4 and 2 mm. We start with a larger diameter. Clamping the drill in the chuck, and the pipe in a vice (marks up), we make a cut in the pipe, pressing the rotating drill with its side in the center of the mark and making reciprocating movements.

The immersion depth of the drill should not be greater than its thickness. The resulting oval-shaped holes with a knife should be cleaned of plastic residues.

Blade insert

The blade inside the pipe must be inserted so that the cutting edge is located exactly in the middle of all the holes. It comes in with a lot of effort (and we need to insert it completely), therefore, to facilitate the process, you need to squeeze the pipe with the other hand from the sides parallel to the plane of the blade, while moving it inward.

After that, we install plugs from the junction box on the edges of the pipe and you're done. You can carry out tests.

How to use a homemade insulation puller

The groove that best matches the cable diameter is selected. The wire itself is laid directly in it so that the knife line is in place, along which the insulation should be removed.

At this point, the wire is pressed with a finger to the inner blade and the wire rotates in any direction. By pressing a finger, the depth of cut is adjusted. Then, holding the wire with the same finger in the recess, with the other hand, pull it in the direction opposite to the device and release the end from the insulation.

The device copes with multicore communications, is easy to use and does not require any maintenance. If the sharpness of the cut is lost, the blade can be replaced with a new one.

When performing work, you must follow the rules for safe operation with a power tool, and also be especially careful when installing a thin blade - it is very easy for them to cut themselves.

As you can see, it’s not necessary to spend money on special devices, when you can do it yourself with free hands no less effective device for stripping the ends of the wiring.