Most of the support stands (or supports) for trucks and cars are usually installed under the stiffener after lifting the "belly" of the machine with a jack. In this article, we will consider the option of a home-made support stand for a car, which is easy to install without the use of a jack.

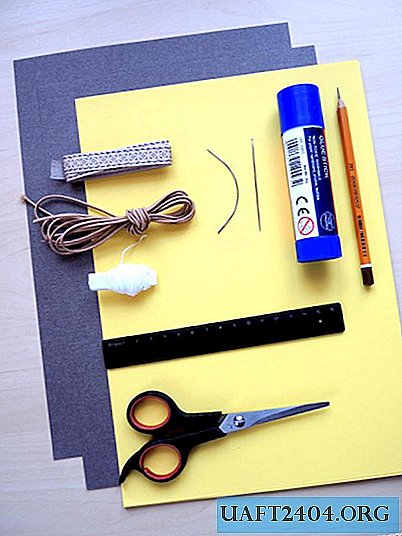

For the manufacture of this homemade product the following materials will be required: two square profiles of different sizes, a piece of a steel plate, two pieces of a round pipe and a steel bar, cut on both sides at an angle of 45 degrees. You will also need a short section of the profile pipe 20x20 mm. All of these materials are easy to find in a garage or workshop.

The main stages of work

First, we make a U-shaped support "heel" of the stand under the lower arm of the car - for this we cut along a piece of thick-walled pipe of suitable diameter with a grinder. In profile pipes, we drill six through holes. From the steel bar we cut two segments that we bend into hooks.

These hooks will fix the height of a makeshift stand-stand. Then we weld a profile pipe of larger diameter to a metal plate - the "sole" of the structure. Next, on one side of the profile, you need to weld a steel bar at an angle, and to the other, a short profile of 20x20 mm and a piece of round pipe.

U-shaped support "heel" is welded to the second profile pipe, which is movable. Then we clean all the details from rust and slag, paint and assemble the rack for the car. It is installed at the bottom slightly at an angle, and to lift the car, you just need to run over it.