Using this homemade ring bending machine you can make rings from steel plates 3-4 mm thick (you can also use smooth and grooved rebars with a diameter of up to 10 mm). The machine for bending rings has a compact enough size - to get started, just install it in a vice.

For the manufacture of a convenient roller ring bending machine at home, the following materials will be required:

- two pieces of the corner 45x45 mm;

- 2 steel bars;

- two bushings from pieces of pipe;

- three bearings;

- bolts with nuts and washers.

The main stages of work

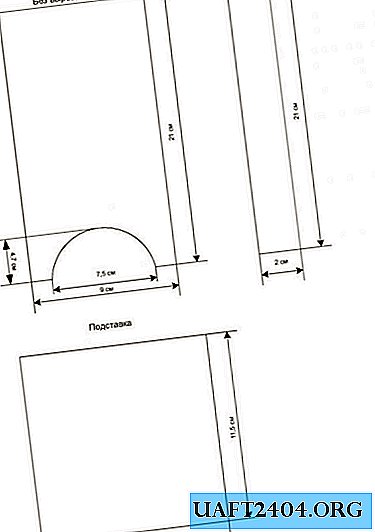

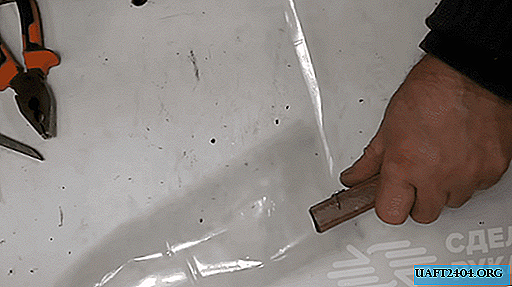

First, we cut two pieces of a corner of 45x45 mm of suitable length, and then drill 2 holes for the guides along the edges. Then, we cut off four identical segments from a regular water pipe with a grinder (if necessary, drill the inner diameter to the required).

As guides we use 2 pieces of steel bar. Next, we connect the corners together, insert the guides into the previously drilled holes, after which we put on them one sleeve on each side (we weld them to the shelves of the corners).

We scald the end face of the sleeve and the guide so that one of the corners is fixed motionless, and the second corner should move freely along the rod. To a fixed corner we weld a piece of steel round timber, on which we put on a large bearing.

On the movable corner, in the same way we fix small bearings. Then we weld the handle to the central bearing housing. See the video on the site for the assembly process of the roller ring bending machine.