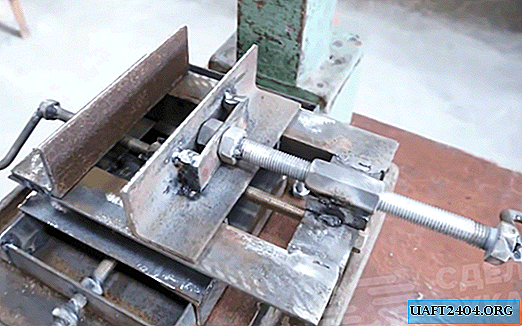

This design of a home-made vise for a drilling machine differs from conventional models in that it is able to move in two planes. This allows you to more accurately expose the workpieces made of metal or wood to drill holes in them.

The main elements of a movable vice for a drilling machine are made of pieces of angle that are connected to each other by welding. Also required are pieces of studs and pieces of metal. In general, the design of the vise is quite budgetary - every master can make it.

The main stages of work

First of all, cut pieces of the steel corner of the right size. From four corners we weld a rectangular frame, exposing them strictly at an angle of 90 degrees. And in short corners, you need to drill holes for the stud.

Then we cut four more segments of the steel corner, and weld from them a movable carriage for a vice, which is installed on the main frame - it will move in the same plane.

A second smaller carriage is inserted into it, which will "walk" in the second plane. It is also made from pieces of corner. Next, we weld a strip of metal to the lower carriage, and to it is an elongated nut into which the stud is screwed.

Then a hairpin is installed that will drive the second carriage. Clamping jaws of a vice are also made of a corner. When all the structural elements are ready, we assemble the homemade product.

The detailed process of making home-made movable vice for a drilling machine, see the video on the site.