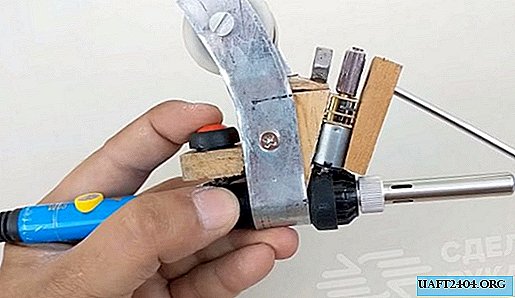

A flexible shaft for a drill or screwdriver allows you to transmit torque to a certain distance. This makes it possible to carry out various work (for example, drilling holes, grinding parts, twisting screws, etc.) in the most inaccessible places.

To make a do-it-yourself flexible shaft for a household electric drill, you will need a cable from the gearbox of the car that is used to switch. One end of the cable must be inserted into the chuck of an electric drill, and a fast-clamping chuck from a screwdriver is attached to the other.

The end of the cable, which will be inserted into the drill chuck, will need to be cut with a grinder to the required length. Then we wash it with WD-40, and only after that we clamp in the drill cartridge. Next, we move on to the next stages of work.

The process of making pens and coasters

At the other end of the gearbox cable, we install a keyless chuck from a screwdriver. After that, you need to make a handle from a wooden block.

First, make a recess under the cable, then glue two halves. Round the handle with a grinding disc for angle grinders, and then smooth out irregularities with sandpaper.

In the next step, you will need to make a stand for the electric drill. To do this, you can take either a piece of board or plywood 20 mm thick. We make the markup, cut off the workpieces of the required size, after which we collect the stand and attach the drill to it.

You can watch the step-by-step process of manufacturing a home-made flexible shaft for a household electric drill in the video on our website.