Share

Pin

Tweet

Send

Share

Send

Advantages and disadvantages of "purchased" sharpening machines

The most common reason for failure when sharpening a knife is the difficulty in holding it in such a position that the angle of approach remains constant. There are many devices and machines that solve this problem.

The main advantage of grinding systems manufactured in the production environment is their readiness for work, nothing needs to be completed.

However, they also have disadvantages:

- Most devices can only work at fixed angles (kitchen electric sharpeners, appliances like Lansky).

- Systems with good functionality, such as Apex Edge Pro (Price around $ 300), cost a lot of money. Moreover, there are more clones and fakes on sale than the originals.

- Almost all mechanical sharpeners remove a huge amount of metal and overheat the cutting edge. Exceptions, such as Tormek (Tormek T9 costs more than 50 thousand rubles in the minimum configuration. Equipment for the machine will have to be bought separately and also expensive.), Are ADSCI expensive.

- Not all "factory" designs fix the blade quite rigidly.

Homemade sharpener

At least a thousand knives, chisels, and other cutting tools have visited the homemade fixture that I use, so I have no doubt about its effectiveness. The design is extremely simple, and the most expensive thing in it is grinding stones. I will not give specific sizes in the description, only general ideas.

Bed

The bed is a piece of iron from the Young Bookbinder set. It is quite dimensional and massive, so it does not stagger even on “crooked” bases.

Rack

The tripod from the enlarger turned out to be an excellent donor. The regular lifting mechanism, which I use to adjust the angle of the stone relative to the plane of the blade, works smoothly and is securely fixed.

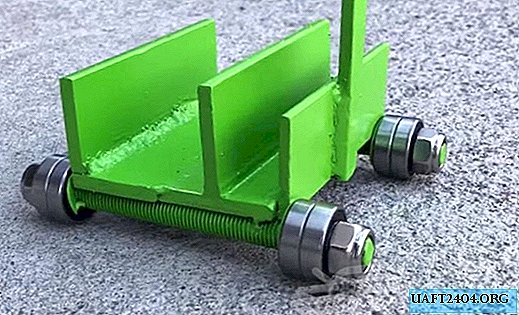

Tilt bar

A calibrated bar with a diameter of 10 mm is designed to hold and move the grinding stone. It is attached to the lifting mechanism through a hinge - a steering tip from karting. The following parts are put on the rod: a plastic nut, a spring, two clamps with fixing screws, a nut on the back (so that the rod does not fall out of the hinge). This design allows you to work with stones of different lengths and change them quickly: I never fix the locking screw of the near clamp, and the settlement is held by the spring force.

Blade fixing mechanism

Elements of the mechanism:

- Bracket. The item is made of duralumin and acts as a clamp.

- The bronze bushing with a semicircular groove is clamped motionlessly in the bracket.

- The shaft is planted with a clearance of 0.1 - 0.15 mm, i.e. it rotates freely. The spring presses the locking axis against the sleeve.

- The channel is fixed on the shaft motionless.

- Two pairs of sponges with M8 hammer bolts move freely along the grooves in the channel. After tightening the nuts, they are firmly fixed in the installed position. The angle between the surfaces of the jaws adjacent to the shelves of the channel is about 75 degrees.

The sleeve is made on a lathe, the sponges and the channel on the milling, the bracket on the drill. The remaining parts and blanks were found in the garage.

Sharpening order

If the knife used is sharpened and it is required to maintain the value of the angle of approach, then the work is performed in the following order.

We clamp the blade in the jaws, after having previously adjusted their position in width.

Before installation, seal the knives with a polished blade with masking tape so as not to leave scratches.

We draw a cutting edge with a waterproof marker. We install an abrasive block with the largest grain. We make several accurate movements of the barbell from ourselves. By abrasion of the traces of the marker, we determine whether the angle is correctly selected. If the stone catches on the edge, then it must be increased, i.e., raise the hinge. After correcting the angle, the abrasive must remove traces of the marker along the entire plane of the cutting edge.

Now you can proceed directly to sharpening. We make reciprocating movements with the bar and move along the edge of the knife until the chips, wrinkles and other defects are completely gone. We make light pressure only when moving away from ourselves. The bar should come back idle. In the last passes, weaken the pressure on the bar.

We pull the channel onto ourselves and turn it 180 °. We sharpen until the approach width on both sides is approximately the same.

For visual inspection of the edges do not need to bend constantly. One of the advantages of the device used is that the knife is fastened once, it can be rotated as much as desired, and it will always stop in the right positions.

When the second side is finished, a burr will appear on the first. You can not see it, but it is clearly palpated by the fingers. You need to make sure that the burr is formed along the entire length, otherwise then there will be "stupid" sections and the work will have to be redone.

The burr must be controlled by finger movements from the butt to the cutting edge, but not along it! Otherwise, cuts cannot be avoided.

The width of the cutting edge along the blade depends on the geometry of the slopes. On this knife, the approach at the tip is thicker than in the rest.

Before moving to a smaller abrasive with a sponge or paper towel, remove the sawdust. We remove the risks from the previous stone on both sides. In this case, the burr should separate: do not crumble in the form of dust, but fall off with thin threads.

Depending on the size of the grain, the second stone can also “kick” a burr. In my case, it was just that. Then go to the next seed.

We check the result of work on the newspaper: we make a cut with a broach and control its smoothness. If defects remain, they will cling.

If you want, you can try to shave the hair on your wrist.

The best way to check is to cut with a knife what it is intended for.

Abrasive stones

I use a set of diamond bars on a metal bundle (4 pieces). Coolant - tap water. Some sharpeners wet diamonds with a soap emulsion. Someone even works "dry" (see video). In accordance with the instructions of the stone maker, I recommend that I recommend wetting the bar with water and periodically rinse off metal filings with a brush.

Grain sizes on whetstones (in microns):

- 125/100 - forming the cutting edge, changing the angle of sharpening;

- 63/50 - rough grinding;

- 20/14 - fine grinding;

- 7/5 - polishing.

I began to work as the first stone, and finished the third. I use the fourth quite rarely, only at the request of aesthetes.

Instead of diamond bars, you can work with artificial corundum stones. There is an even more budgetary option: stick strips of sandpaper of different grain sizes on aluminum or glass blanks. Most importantly, all stones in the kit must be the same thickness.

Knife sharpening video

In the video, the huntsman sharpens his working knife (Bohler M390 steel) on the fixture described above. He uses only one 63/50 stone and believes that this is enough. Characteristic movements along the edge - this way it removes the burr.

Perhaps I missed something in the description of the process or device, deviated from some canons, do not pray for Arkansas and Japanese water stones. I propose to discuss these points in the comments.

Share

Pin

Tweet

Send

Share

Send