Share

Pin

Tweet

Send

Share

Send

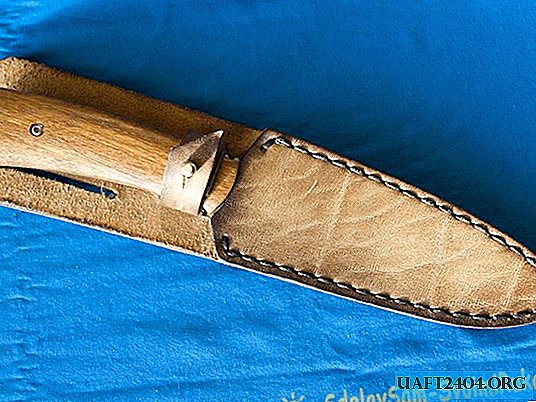

Quite often, visiting and shopping at hunting and fishing stores, I noticed for a long time one interesting little thing - the “Gasoline Match” is called. Or the “Eternal match”, as it is also called ... Here is how it looks in the original:

The thing is quite curious, useful and interesting, it must be in the backpack of any tourist, fisherman or hunter. It can be a good help in some force majeure, or emergency situation, it is not afraid of rain, it will not get wet in the fog and in general, it does not care for any moisture - even if it falls into a puddle, stream, or wet snow. In addition, she is not afraid of any wind, it is almost impossible to extinguish it like an ordinary match, with a wave of the brush (a good example in the video, at the end of the article). It works on the principle of a gas lighter, only here, instead of a rough wheel - a chair with sharp edges. Having examined this product in the store more carefully and in detail, I thought, why not do it yourself? In fact, nothing complicated - a capacity of about 3-4 cubic centimeters, a metal tube, a flint and a chair. Not that I was sorry to give a hundred for her ... No. The interest just appeared - will it be possible or impossible to do the same on its own? The most problematic was to get a ferro-cerium rod (this is flint as in a lighter, only long). Having visited many sports, fishing, hunting and tourist shops, somehow I still found the required. It was probably easier to order in the online store, there you can buy this product of any kind, size and price ... In general, having prepared all the necessary material and tools, I got down to business.

Will need

- Corrosion-proof tin (for the case).

- A metal tube with a diameter of 3-4 millimeters and a length of 4 centimeters.

- Two threads; internal and external (with thread similar to the wheel cylinder nipple system).

- Ferrocerium rod, with a diameter of 2 millimeters and a length of 5 centimeters.

- Rubber gasket.

- A piece of steel sheet for metal (1-2 centimeters, for a chair).

- Cotton wick.

- A piece of cotton wool for the filler (synthetic winterizer can be).

Tool:

- Scissors.

- Soldering iron, flux and tin.

- Pliers.

- Round pliers.

- Ruler.

- Marker.

- Sandpaper.

- Boron machine or emery machine.

Making an eternal gasoline match

First, we will deal with the most time-consuming part of the manufacturing process - the body. When making measurements, it is necessary to be extremely accurate and attentive. A small error, even in half a millimeter, will lead to the fact that the capacitance turns out to be combined and curve. So, first we cut a piece of stainless steel, a square of 50 × 50 millimeters.

Next, we measure in the middle a strip 1 cm wide, and with the help of a ruler and round-nose pliers we bend the edges from the marked strip.

The following workpiece will turn out:

Now cut another strip of tin, 5 × 1.5 centimeters and bend it with pliers along. We make a corner of about 90 degrees, here the accuracy is not so important, if the corner turns out sharper, or blunt - it's okay. The angle is needed in order to lay the ferrocerium rod in it.

Next, we heat the soldering iron and, having previously processed the edges of the workpieces with sandpaper and flux, we tin the edges of both workpieces with tin. And solder both workpieces. The tip of the corner is inward.

Now solder the ends. To do this, attach the soldered blank to the piece of sheet metal, mark the edges with a marker, and cut out the bottom end wall. Solder it to the main workpiece.

Unforgettable before soldering all parts, tin the edges of the workpieces, otherwise the container will not be airtight. Now let's get down to the top. We will have it with an external thread on which a match-cap will be wound. We also cut the end wall out of tin, drill a hole in it, of the same diameter as the internal diameter of the thread. Solder the thread to the hole in the end wall. Now solder this threaded end to the main workpiece.

At the end, we remove the sharp corners with a file, the protruding tin protruding outward and clean everything with an emery cloth. You can also polish all this on a felt with goy paste, so that it shines, but I did not. The matte metal surface is more to my liking than polished to a blue color - not so easily soiled ... Well, the container is ready.

You can check the tightness of the container by screwing it onto the pump hose (the threads are identical) and once having pumped the pump, lower the container into water. Everything will become very clear where and what needs to be soldered. Now we’ll make a cover with a “match” soldered into it. Here, everything is as simple as possible, we put the internal thread as evenly as possible on one of the ends of the tube and solder this end of the tube to the center of the thread. Like this:

We process the soldered place with a file and sandpaper, thereby removing excess tin. Next, using a boron machine (or emery machine), we cut out a small strip from a piece of metal sheet. It will be the chair itself. The strip should be small, but for effort to enter the tube. You can even leave small spacing-stops so that the strip of steel does not fall into the tube entirely.

Now we hook the wick on top of this chair and install it in the tube as it enters. It is necessary that the tip of the steel chair sticks out of the tube. Trim the wick.

The match cap is ready. Next, we push the remnants of the wick, cotton, synthetic winterizer into the tank, in general, everything can be soaked with gasoline, and install a rubber gasket to prevent gasoline vapor from escaping in the future.

Just do not forget to leave inside the place for the match itself. Now we lubricate the inner corner of the container with second glue, and attach a ferrocerium rod to it, wait until it hardens, and refuel gasoline. It is advisable to special cleaned for lighters, for better ignition.

That's done. You can use it. Let's hope that we do not have such situations in which we have to use this thing, but, as they say, it is better to have and not need than to need and not to have!

Check

We get a match.

Striking.

It burns perfectly.

Share

Pin

Tweet

Send

Share

Send