From a profile pipe 150x150 mm, as well as two bearings of different diameters, you can do it yourself do-it-yourself universal home-made device for the manufacture of parts, from which it will be possible to weld a decorative steel grill on the windows, as well as other elements of the enclosing metal structures.

Using this simple conductor, you can bend metal bars of circular cross section under different radii. The output produces the same wave-shaped blanks, which are then used to weld decorative gratings or for the manufacture of other elements by the method of artistic forging of metal.

The main stages of work

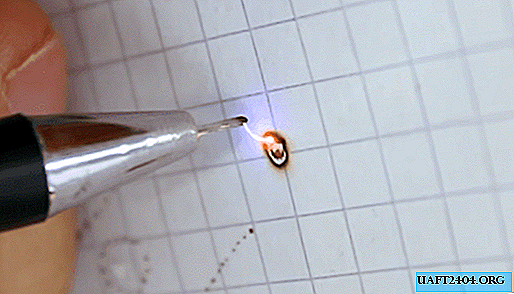

To make a universal jig template, you will need to find two bearings of different diameters. We clamp them one by one in a vice, and then with the help of an angle grinder we cut the outer clip in half, pre-marking with a marker so that both halves turn out to be the same.

Then we cut off a piece of the desired length from the profile pipe 150x150 mm. On the one hand, you need to weld two halves of the cage of a large bearing, on the other - a small one. Also, at a distance of about 2-3 cm from the edge of the ferrule, a thrust nut or piece of square must be welded.

At the last stage of work, we clean the surface of the metal with a grinder. If desired, the surface of the metal can be painted for a more aesthetic look of homemade work. A homemade conductor is clamped in a large vice, after which you can begin to work.