Dremel is an indispensable thing for a home workshop. With it, you can perform a wide range of operations for machining metal and wood. However, factory models are expensive, so in order to save money, you can assemble a homemade drill with a flexible shaft.

The main components for assembling Dremel can be inexpensively bought on Aliexpress or other trading floors on the Internet. You will need a flexible shaft itself, an 775 electric motor, a controller board with adjustable engine speed, a bracket for mounting the motor, a 5.5 connector and an adapter for a flexible shaft.

It will also be necessary to make a housing in which it will be possible to place the engine and other components. To do this, you can use planks or trimmed plywood, which will need to be cut to size.

The main stages of work

In a wooden board, we drill holes for installing an arm for an electric motor. Next, we fasten the engine itself, and also fasten the back and side walls to the base. In the front wall we drill holes for a flexible shaft and a speed regulator.

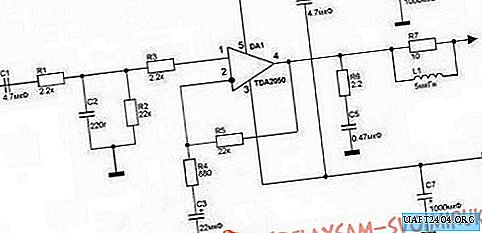

In the rear wall of the wooden case, we drill a hole for the power connector, as well as small holes for air intake. After that, we carry out the wiring - we connect the contacts of the motor with the RPM board and the power connector.

Then, using an aluminum adapter, we connect the flexible shaft to the motor shaft, connect the plug from the power supply and check if everything works. If everything is normal, we fix the cover on top of the case.

The detailed process of making a homemade dremel with a flexible shaft for working in the home workshop can be seen in the video on our website.