Natural planed veneer is suitable not only for the manufacture of furniture. From it you can also make a cool wooden knife according to old Japanese technology. The thickness of the veneer should be approximately 0.6-0.8 mm.

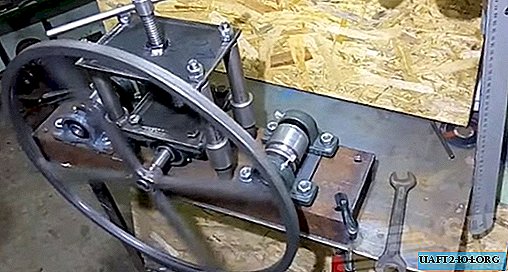

The first step will be to cut the veneer into the workpiece. And for this it is better to use not a regular knife, but a special file. It can be made independently.

To make the Japanese wooden knife original, it is best to use two types of veneers with approximately the same hardness: ash and American walnut. Other combinations may also be used.

The main stages of work

From the prepared segments of natural veneer we make two piles: one for the blade about 5-6 mm thick, the second - already for the handle (about 20 mm thick). Then we prepare the clamping strips of wood and glue the workpieces with epoxy.

After about 24 hours, after the epoxy hardens, you can begin machining the workpieces. First we remove the “snot” of the epoxy with a knife, and then we level the surface of the veneer with a grinding machine.

At the next stage, we cut the shape of the knife with an electric jigsaw (it will be necessary to turn off the pendulum stroke) or with a hand hacksaw. You also need to cut two pads for the handle. Then we glue the workpieces together using epoxy.

Next, we grind the workpiece and sharpen it. Details on how to make a wooden knife from veneer using Japanese technology can be found in the video on the website.