The Bulgarian has long passed from the category of a conventional household electric tool to the category of a universal tool. A small angle grinder can replace many other tools (but the main thing is to observe safety precautions).

An angle grinder can be used not only for cutting, sharpening or grinding metal workpieces manually, but also as a mini desktop machine for working with metal or even wood.

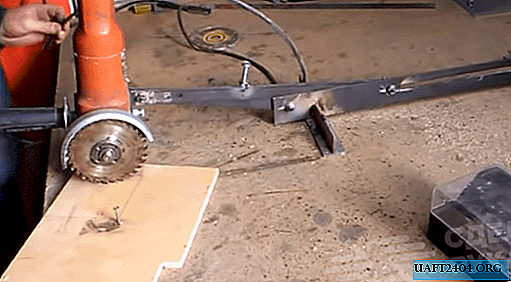

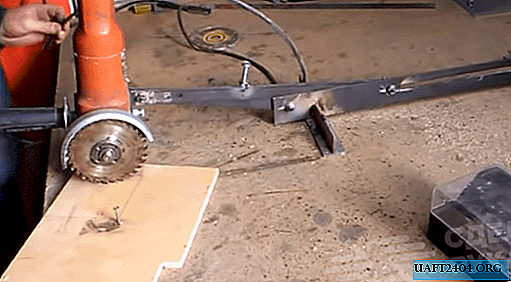

First of all, from a metal strip with a width of 50 mm and a thickness of 3 mm, we cut off a workpiece with a length of 50 cm. Using a grinder, we make a longitudinal long slot in the middle. We drill along the edges of the hole and knock out a thin strip.

The main stages of work

At the next stage, we cut a piece of strip 35 mm wide and 3 mm thick 52 cm long. We will also need to cut three pieces of the strip 27 cm long. Then we mark and drill through holes. We connect two workpieces with a piece of a hairpin or a bolt without a hat.

Then we fasten a long strip with a width of 3.5 mm to a strip of 50 mm using a bolt with an M8 nut. If necessary, the excess part of the bolt can be cut off with a grinder. Next, cut off 2 pieces of the T-profile, and make vertical cuts. We install the assembled structure.

At the last stage of the work, we weld together the main elements of homemade work, then we make the “ears” of the plates, and install the grinder. For details on how to make a simple desktop mount for a small angle grinder, see the video on the site.