In any home workshop or garage, a homemade press is useful. For its manufacture, channel number 80 is used. For this design, a length of 400 mm will be sufficient. You will also need a profile pipe 40 * 40 mm and a strip of metal 25 mm wide.

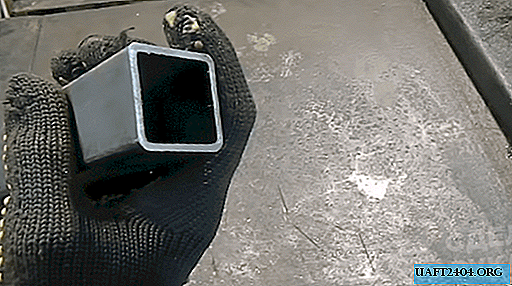

On the channel, two holes are made for the guides of the future matrix. With the help of a core marking is done. Then we take a profile pipe 40 * 40 mm and make two workpieces from it, each 50 cm long. Note that the edges of the workpieces should be at an angle of 45 degrees.

The wall thickness of the profile pipe should be at least 3 mm. Thus, there are all the components for assembling a homemade press - you can proceed directly to the assembly.

The main stages of work

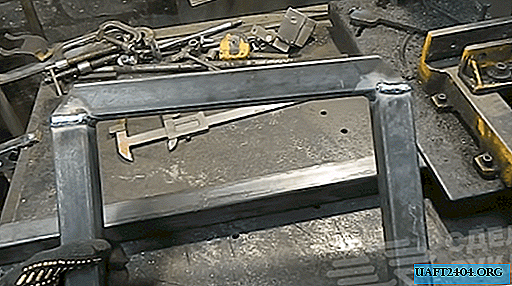

First of all, it is necessary to weld the frame, while it is desirable to make high-quality seams. Additionally, emphasis needs to be made. For this, the material used for the frame is suitable. During welding, the angle must be observed very carefully. This requires the use of a square.

At the next stage, we weld previously prepared parts to the profile and fasten two springs. As you can see, making a homemade press using a jack is quite simple, and for this you will need simple structural materials.

If you do not have experience in implementing your design ideas, then you can use the drawings, of which there are a huge number on the Internet. A homemade press for a workshop from a jack can be used not only in the garage for car repairs, but also for solving various household problems.

The press, assembled by oneself "on the knee", is practically in no way inferior in technical characteristics to models manufactured in industrial conditions. For a more detailed overview of this homemade product, see the video on the site.