An old metal drill bit that has broken down or has already “unwound” its life can be milled to process non-ferrous metal workpieces (aluminum, copper, brass, etc.). And for this you will need an emery machine.

The master plans to use a homemade milling cutter on a lathe, so if you have a lathe in the garage or workshop, then the very idea of converting a drill into a milling cutter may come in handy.

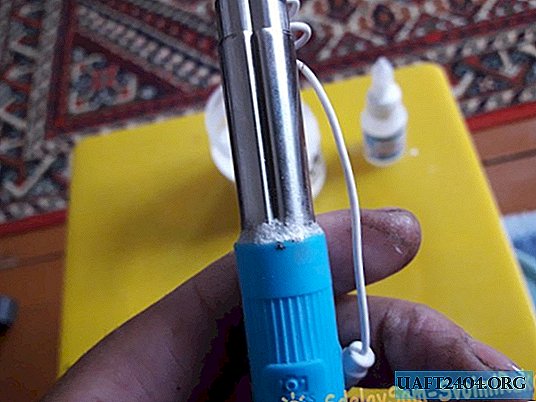

First of all, it will be necessary to align the end of the drill with metal. This can be done either on an emery (grinding) machine, or using a grinder. After that, you can proceed to the regrinding of the drill itself.

The main stages of work

Next, on the emery, it will be necessary to carefully remove the back of the cutting edge of the drill. In this case, the cutting edge itself must be left untouched.

Please note that during the regrinding process you need to turn the drill bit a bit. It is also important not to overheat the metal. Otherwise, the drill will lose its properties.

The final finishing of the cutter is best done on the diamond wheel. But if this is not at hand, then you can try with an ordinary stone. Then you can put it on a lathe and try to process the workpiece.

For a detailed process of making a home-made cutter for non-ferrous metals from an old metal drill, see the video on the website.