In this review, the author shows how to make pipe clamps with your own hands. This will require round pipes.

The first step is to cut the blanks from round pipes. The length of the workpieces depends on how long you need a clamp.

After cutting the workpieces of the required length, they will need to be cleaned with a grinder from old paint and rust.

Be sure to do this work in a ventilated area and in a respiratory mask. It is also advisable to wear safety glasses.

The main stages of work

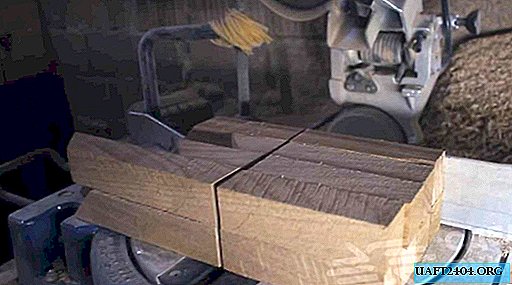

In the next step, it will be necessary to cut out the jaws for the clamp and the handle. A craftsman carves these details from wood.

The blanks that are used to make the pens will need to be slightly rounded (not along the entire length, but only the edges).

This work is conveniently performed on a lathe from a drill, which you can do yourself. Read more about this in this article.

After you made wooden handles, you can start making sponges: one will be motionless with a nickle, and the second will be movable.

In the clamping jaws, it is necessary to drill holes for the pipe and make a cut so that you can tighten them with bolts.

At the last stage, it remains only to assemble all the details into a single whole. For more information on how to make a clamp for a workshop from steel round pipes, see the video on the website.