In this review, the author decided to sacrifice two clamps to make vertical clamps for the workbench from them.

To implement his idea, the author uses quick-clamping clamps. But you can also use conventional F-shaped clamps.

See also: homemade clamp for a standard F-shaped clamp.

First of all, the author removes the upper clamping jaws (which are motionless). Next, mark the places where it will be necessary to drill holes in the table (workbench).

The main stages of work

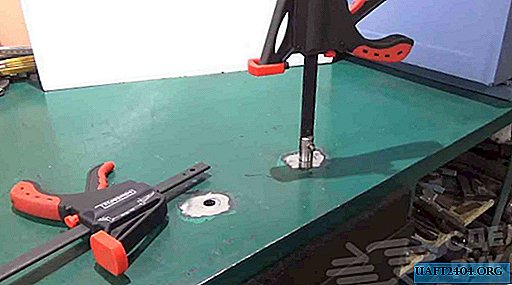

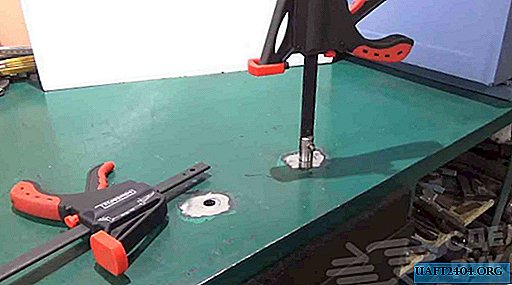

After marking, drill holes of the required diameter in the workbench. If the workbench is metal, first we drill holes with a drill of a smaller diameter, then a larger one.

On a lathe, the author makes two blanks from steel round timber.

They will need to make a groove for the clamp bus, and drill a hole for fixation on the side with a bolt and nut.

Please note that the lower part of the round billets has a smaller diameter than the upper.

At the next stage, we insert bushings into the holes drilled in the workbench, and scald them. And then we insert “fingers” made of metal round timber into them.

Details on how to make clamps for a workbench from two clamps can be found in the video on our website.