Share

Pin

Tweet

Send

Share

Send

Materials:

- sheet steel 20 mm thick;

- smooth rod d 10mm;

- square rod 14x14 or 20x20 mm.

Assembling a chain machine

To make the base of the bending machine, it is necessary to cut a 12x20 cm blank from sheet steel. You can use your own dimensions, but if the workpiece is larger, the finished machine may not fit in an ordinary vice. Then it will have to be screwed to a table or a large wooden deck.

A pair of bending jaws are cut from the same steel. Their size is 3x10 cm. One end of each sponge needs to be rounded, processed on an emery or grinded with a grinder.

Next, the surface of the jaws and the previously made base of the conductor should be sanded with a petal circle.

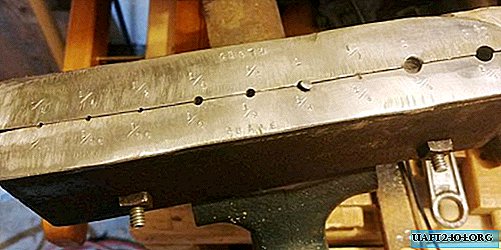

On prepared sponges, you need to make 2 holes. The first is drilled from the rounded end.

Its diameter should be 11 mm. The center of the hole is located at a distance of 15 mm from the ground end and the side edges. The second hole is removed from the first by 1-1.5 mm more than the thickness of the rods that will be used for the manufacture of chains. A drill of 10 mm is used for it. Since it is difficult to drill such a thick metal, thin holes should be made first and then expanded to the desired diameter.

Also, with a 10 mm drill, 3 holes are made on the base of the conductor. Two of them are located in one line. The distance between their distant edges should correspond to the length of the desired links. The third hole is drilled centrally indented to the side by the thickness of the rods for bending.

5 pins must be cut from a smooth steel bar d 10 mm. Three of them are 60 mm long, and two 40 mm.

Handles from a square are welded to the lips. The longer they are, the easier it will be to bend the links. It is advisable to cook the handles at an angle upward, as in the photo, so that in the future it would be more convenient to grab and pull them together.

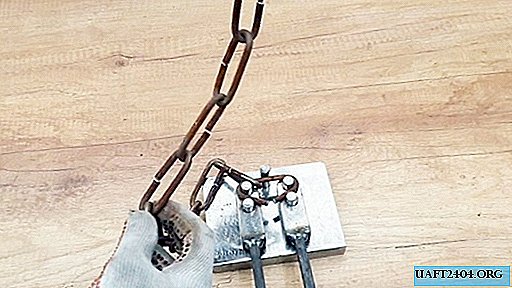

Long pins are driven into the base of the machine, and short pins are pressed into the holes in the holes near the handles. Next, the handles with jaws are put on the pins in the base.

The finished machine is clamped in a vice. Pre-cut steel bars are laid in it and bent by the movement of jaws into the links. The length of the bars is selected individually for the size of the resulting machine. Each subsequent rod is previously threaded into the previous link. After making the chain, the joints of the links are welded.

Share

Pin

Tweet

Send

Share

Send