Share

Pin

Tweet

Send

Share

Send

What tool do we need

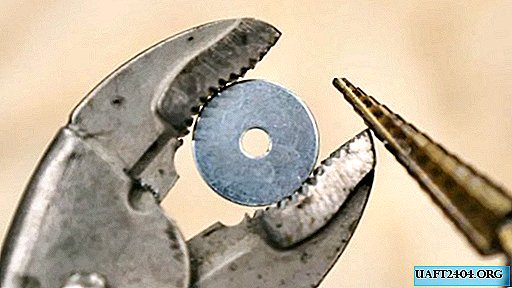

- Universal clamping wrench with lock;

- Screwdriver;

- Step (conical) drill for metal;

- Washer, the seat of which must be increased.

Washer fixing

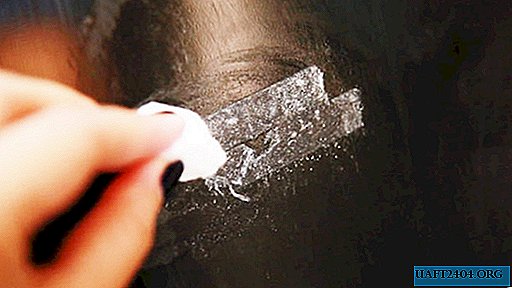

The best solution for convenient grip of the nut is the availability of a special quick-release key with a lock. It is enough to clamp the washer in its slots, tighten the adjustment bolt and tighten the lock. In the absence of such a key, do not despair - there are several ways to reliably fix the washer for drilling. For this, you should use a conventional vice - the main thing is that the metal pancake be clamped without distortions, otherwise even the slightest pressure of the drill will lead to its instability.

In the most extreme case, you can use ordinary pliers and a wooden backing that is securely fixed to a workbench (or anywhere else). By immersing the drill in a more pliable tree, we provide a fixation of the location of the screwdriver and the washer. Holding the last one by the edge with pliers, we prevent its scrolling.

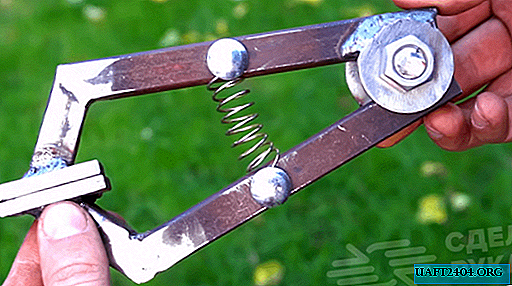

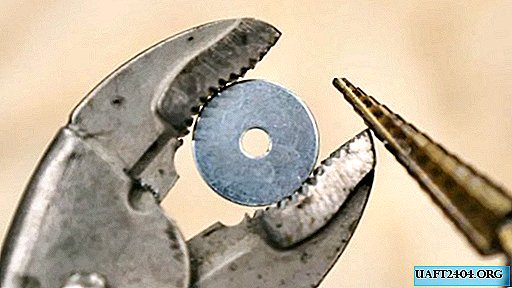

Step drill

One cone drill can replace not only a set of drills, but also crowns for metal. As a rule, it is of high quality and is made of high-speed steel (it can also have diamond spraying, etc.), therefore, there is no need to use special efforts to drill the washer. As a rule, not the most durable metal is usually used for their manufacture.

We insert the cone into the inner hole, activate the drill (screwdriver) and carry out continuous pressing with a drill for 2-3 seconds. After we unfold the washer and drill it on the other side. This will be enough to increase the diameter. We test the work by inserting a bolt into the washer. In case of the slightest clues, repeat the procedure.

Work Summary

As you can see, there is nothing complicated in getting the washer of the right diameter. Despite the fact that this procedure is extremely simple, in no case should you neglect the rules of safe operation with a power tool.

Share

Pin

Tweet

Send

Share

Send