Share

Pin

Tweet

Send

Share

Send

By screwing a self-tapping screw into a solid tree, you can encounter tearing a notch on his hat or tearing off the head itself. As a result, a screwdriver or screwdriver can no longer unscrew damaged hardware. Despite such difficulties, it is possible to remove a damaged screw, and in several ways.

Restoring a notch on a soft hat

In soft screws, a notch on the head breaks even when screwing in, so then it is problematic to dismantle it later. This problem is especially common on door hinges, since the gold-plated self-tapping screws that come with it are worthless. But they can be unscrewed if you take a good bit from a screwdriver and a couple of blows of a hammer as a chisel squeeze a new notch in the head.

Extractor application

For screwdrivers, special threaded steel extractors with a thread are sold that can cut into a self-tapping screw and get stuck in it. After the nozzle is unscrewed already with a screw. Such a device will help even with licked bolts.

Warming up the screw

This method allows you to unscrew the self-tapping screw with a damaged cross, if it is still partially preserved. Using a soldering iron or iron, you need to warm up the fastener cap. From heating, the wood near it will dry out, so the actual diameter of the planting hole will increase. Of course, this will expand the metal screw itself, but after cooling it will return to its usual volume. Perhaps after this a weak notch will be enough to unscrew the fasteners.

Groove in wood around hat

If you are doing rough work when the surface aesthetics are not so important, you can simply cut a groove in the wood around the hat, then grab the screw with pliers and unscrew it. The method will help if the self-tapping screw is not long, and the wood is soft, because otherwise it will take more effort than you can develop by hand.

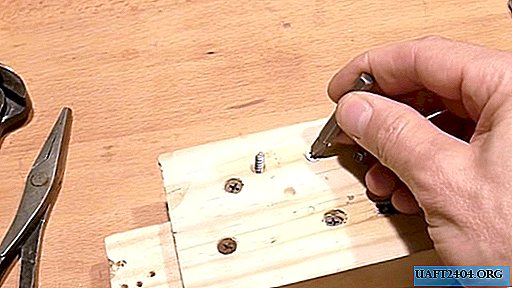

Knurled notch on the screw shaft

When screwing long balls into a solid tree, a hat often comes off, after which only a threaded rod sticks out. If he does not twist it with pliers, then a groove must be cut on it with a file edge or a hacksaw for metal. After that, you can try to unscrew the fasteners with an ordinary flat screwdriver.

Drilling fasteners with wood

You can simply drill a hole around the screw with a pipe cutter or a core drill.

Since such nozzles are drilled only along the rim, the screw itself will remain intact. Having gone deep enough distance, you can simply break the self-tapping screw together with the surrounding wood. In the center there will remain a large hole that needs to be clogged with an insert of a suitable diameter, if then the surface is painted, then the defect will be imperceptible.

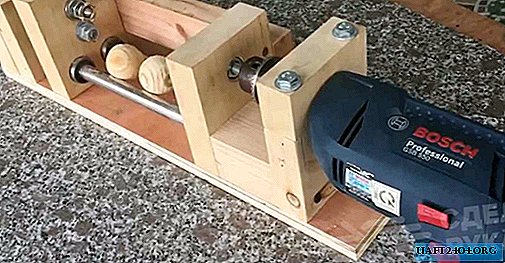

When drilling with a factory or home-made cutter from a steel tube, it is difficult to hold a breakaway drill, so it is better to use a drilling machine.

If you need to work with a drill or a screwdriver, then for positioning the cutter it is possible to use a home-made stop from the plank. It is enough to drill a through hole in it and apply the template to the screw head, and it will not allow the cutter to move to the side.

These methods will allow you to remove fasteners even from solid wood, regardless of the degree of damage. Of course, you need to tinker, so if you have to screw bad screws into a solid wood, it is better to lubricate the surface of the thread with wax or soap. Such fasteners are easier to twist, so the situation with breaking off the hat or breaking the notch will happen less often. Unfortunately, if a screw has been in wood for a long time and needs to be unscrewed, then wax with soap will not help anymore, so you will have to use one of the proposed methods.

Share

Pin

Tweet

Send

Share

Send