Share

Pin

Tweet

Send

Share

Send

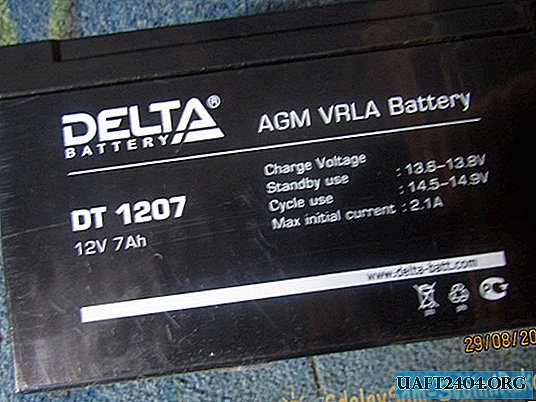

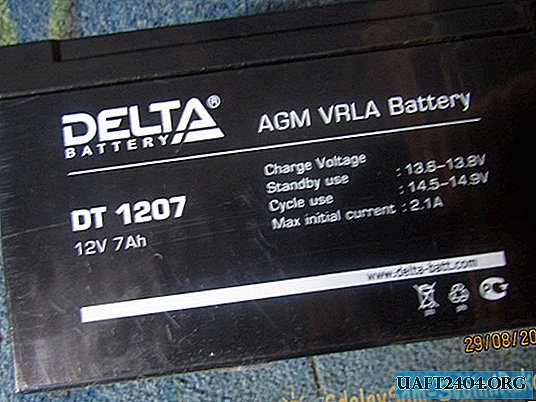

So, lead batteries are susceptible to sulfation. This is a process in which battery plates are coated with sulfate. From this phenomenon, the battery deteriorates in capacity and current.

In order to get rid of sulfate deposits, I will expose the battery to high voltage at high frequency.

I will take high voltage from the power board of the mercury lamp of the document scanner. I will not show how to find it in the scanner and connect it, as this is individual for each scanner.

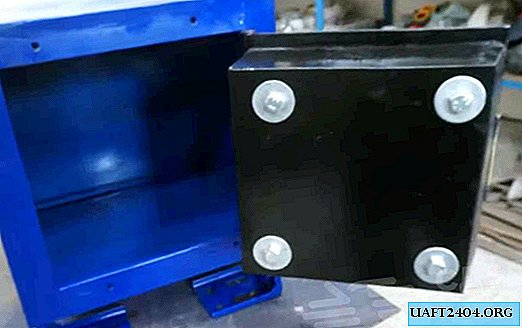

At the tip of one of the high-voltage wires I connect a copper plate at the edges covered with an insulator. And we fasten the second high-voltage wire to the battery terminal.

Moving on to battery recovery

After that, we supply power to the 12 Volt board. Attention! Dangerous voltage!

Now you need to clamp the plate on the second terminal of the battery so that there is no direct contact. And the current passed along the shortest possible spark arc.

To get the best result you need. Beat a high voltage battery from 30 minutes to 3 hours. After disconnecting this design and put the battery on charge. After discharge and repeat all over again.

Repeat until the pack battery capacity increases.

You can also hit with a shaker. This technique applies to ni-cd batteries.

Share

Pin

Tweet

Send

Share

Send