Share

Pin

Tweet

Send

Share

Send

Almost every radio amateur faces the problem of an overheated soldering iron when the tip is heated more than necessary. Soldering with such a soldering iron is not very convenient: the solder begins to change color, covered with an oxide film, the flux instantly evaporates or generally begins to shoot, etc. The way out can be very simple.

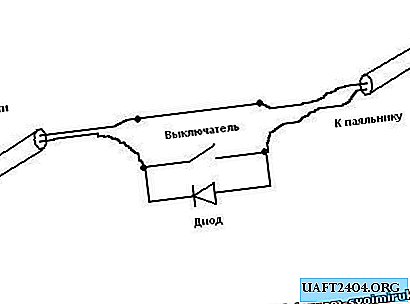

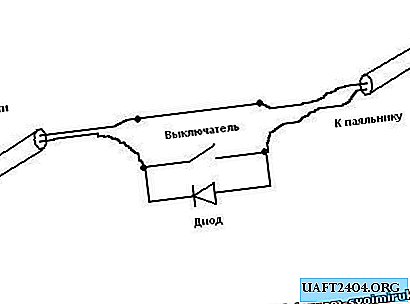

We need two things, this is a wire switch (which is mounted directly on the wire) and a diode with a reverse current voltage of at least 250 volts and a current of more than 0.5 amperes (depending on the power of the soldering iron, based on 100 W = 0.5 A).

Let's proceed to the assembly. To do this, in a place convenient for you, it is necessary to open the insulation of the current-carrying wire, namely one of the wires and connect the switch. Mount a diode in the switch by connecting it parallel to the switch contacts. See the diagram.

We collect, turn on, check.

The device works like this: when the contacts of the switch are closed on the soldering iron, 100% of the power goes, respectively, the tip is heated for the same amount. This mode is used to quickly heat up the soldering iron. As soon as the soldering iron has warmed up (5-20 min.), Turn off the switch. When the switch is off, the current will go through the diode, and the diode will pass only half the phase of the alternating voltage and therefore 50% of the power, the temperature of the soldering iron will decrease.

I have a 60 watt soldering iron. The temperature in the second mode is excellent for soldering the most common solders. I also had a soldering iron with a power of 100 and 30 watts with this regulator, it was also pleasant to work with them without overheating.

I want to note that with the use of this simplest regulator, I completely lost the desire to craft more complex ones or buy expensive ones.

But still I want to offer another version of the regulator. I did not use it myself, but my friends say that this regulator is not bad at work.

This is the idea. In electrical goods stores, ready-made regulators are sold, though for lighting devices. In appearance, it is slightly larger than a conventional switch and can be successfully applied to a soldering iron. See picture.

The disadvantage of such a regulator is its "invisibility of adjustment." In other words, if it is used for a light bulb, then obviously we see the level of adjustable brightness. And with a soldering iron, everything is sad. You can not visually surprise his temperature and you have to twist it from case to case. But there is still a way out. You just need to calibrate the regulator and mark the position with a marker.

Whatever regulator you choose when installing or commissioning, do not forget to disconnect it from the network! Good luck.

Share

Pin

Tweet

Send

Share

Send